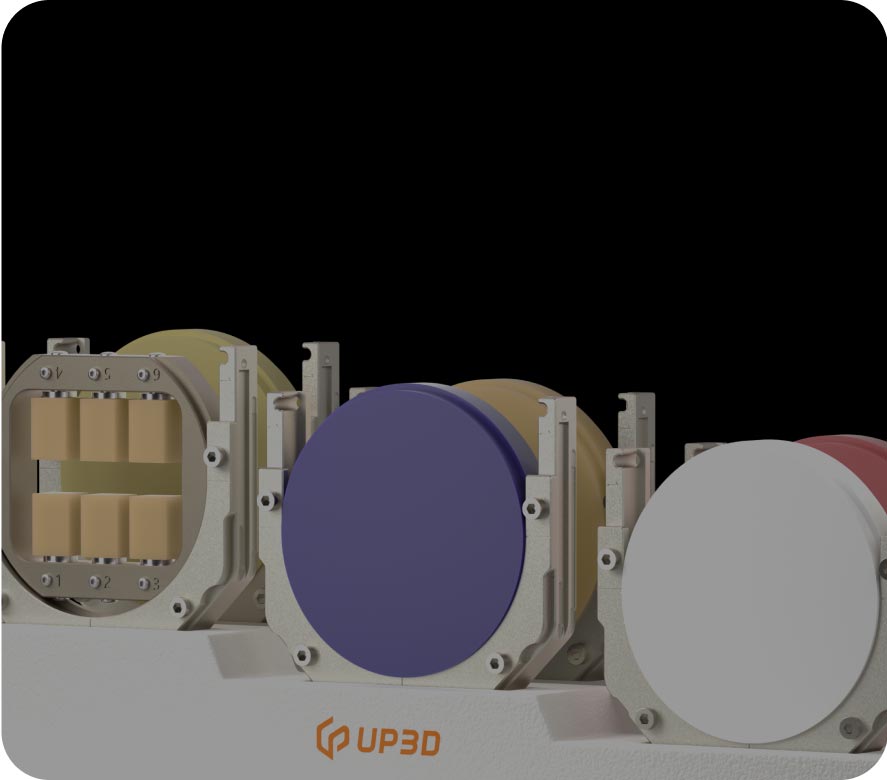

Automatic Disc Changer

Automatic Disc Changer Smart Material Management System

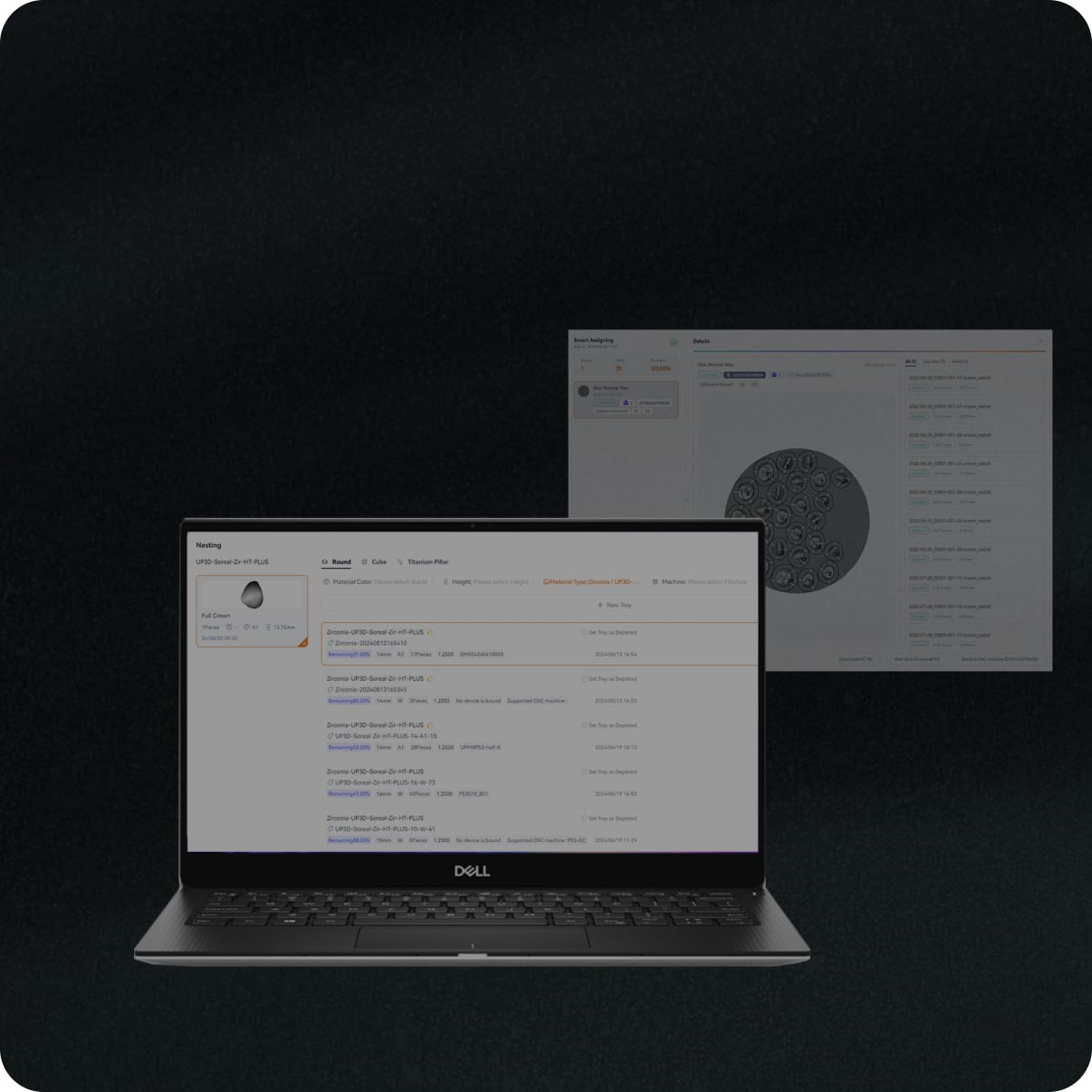

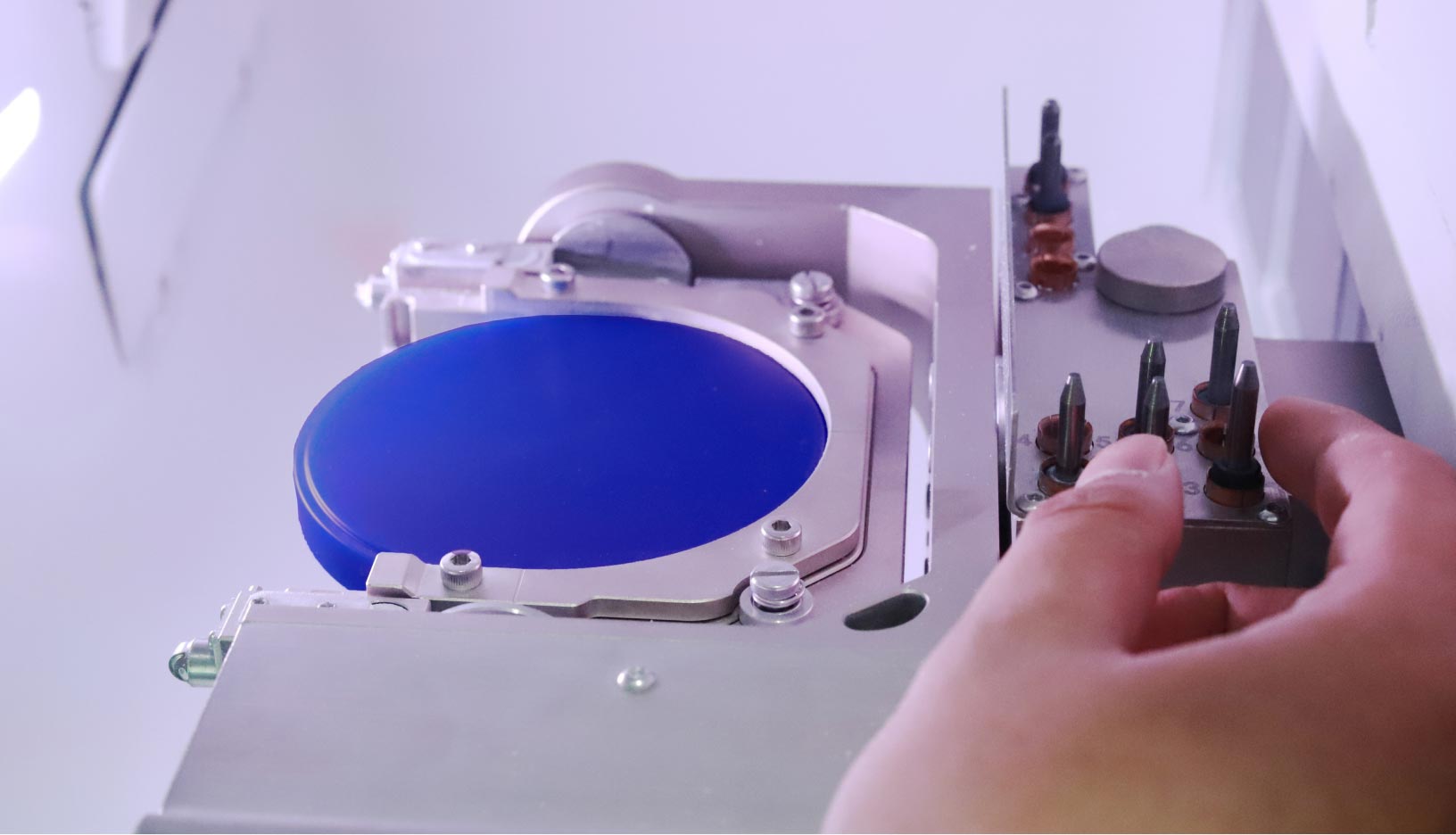

Smart Material Management System Automatic Tool Changer

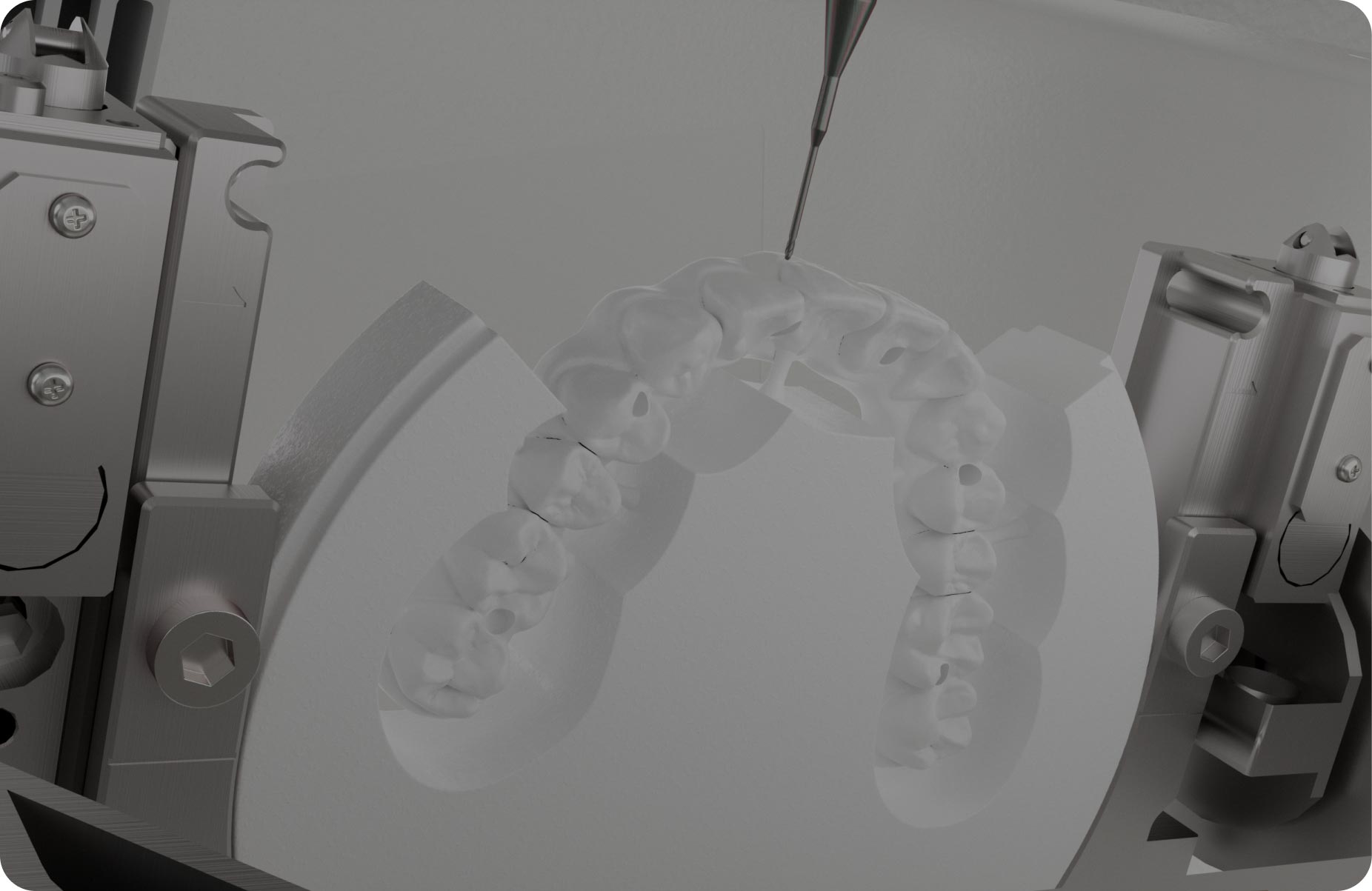

Automatic Tool Changer C-Clamp 90° Milling

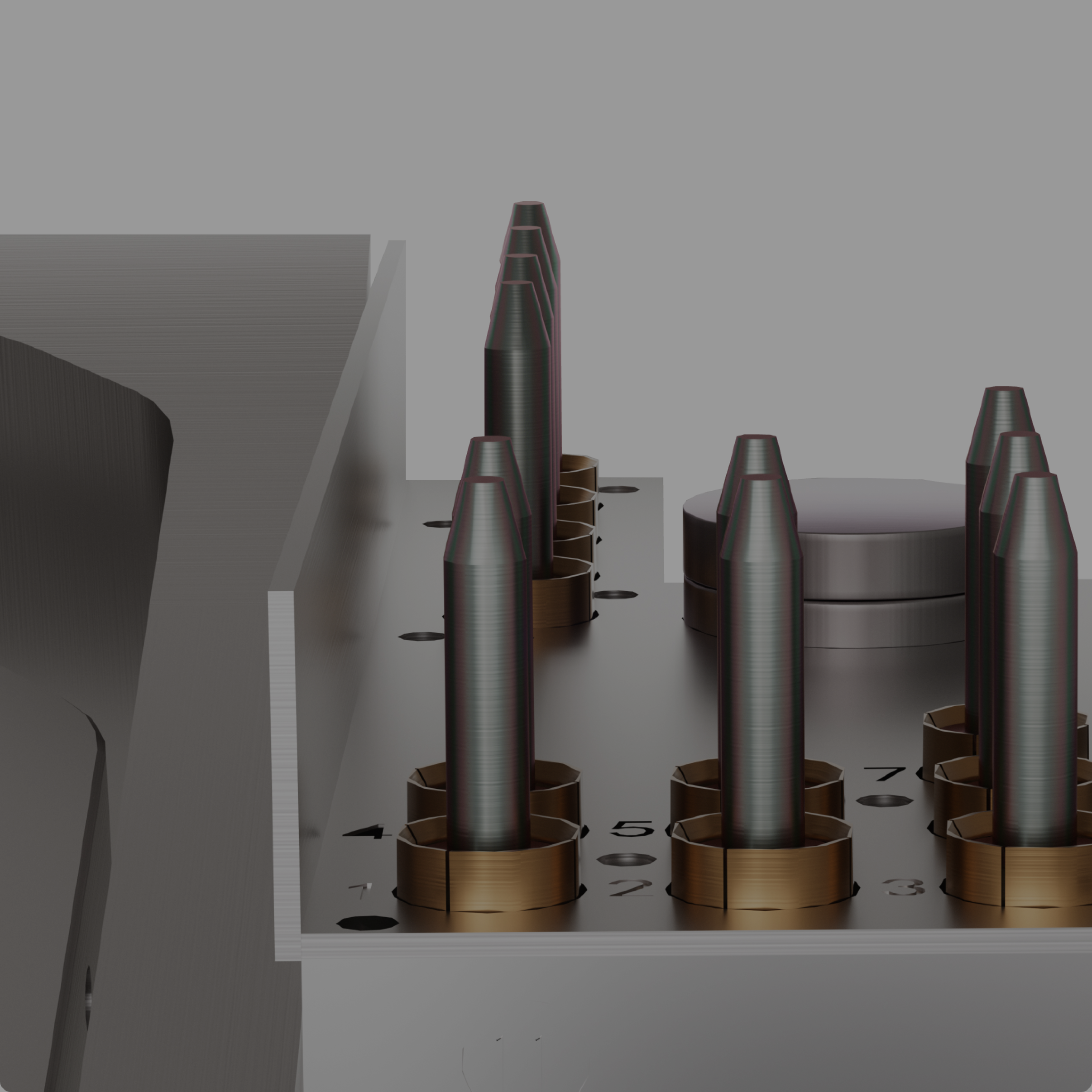

C-Clamp 90° Milling Enhanced ionizer

Enhanced ionizer Custom Strategy for Precision Milling

Custom Strategy for Precision Milling Pre-Loadable Material Adapters

Pre-Loadable Material Adapters Smart Disc Identification Technology

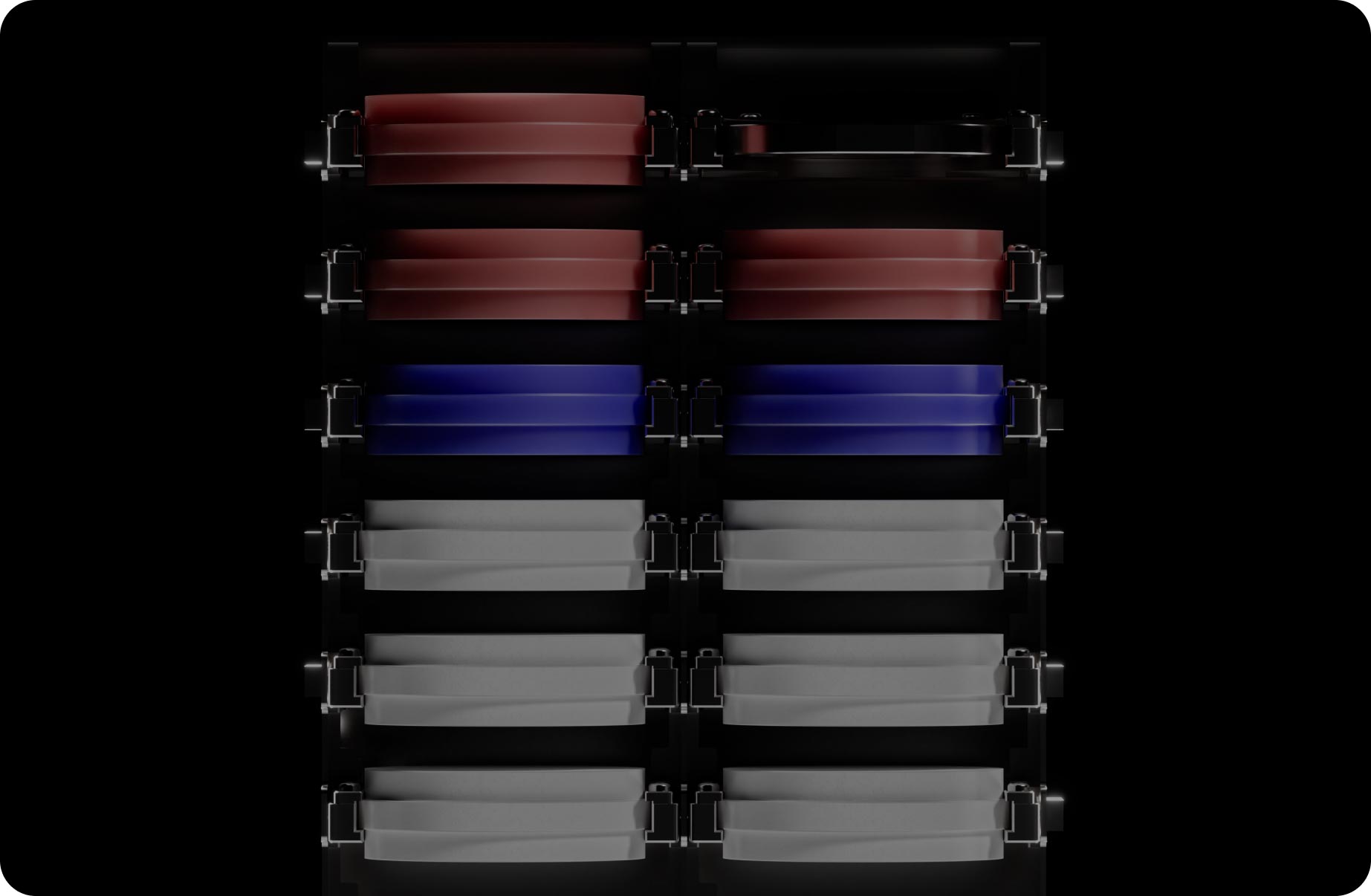

Smart Disc Identification Technology.jpg)

.jpg)

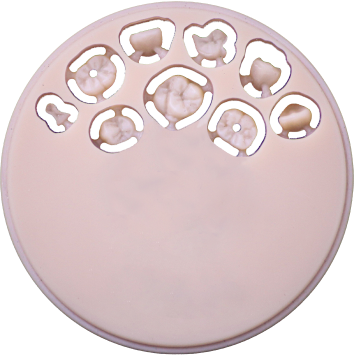

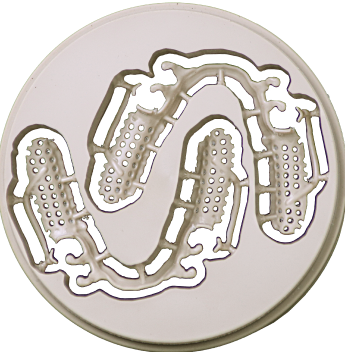

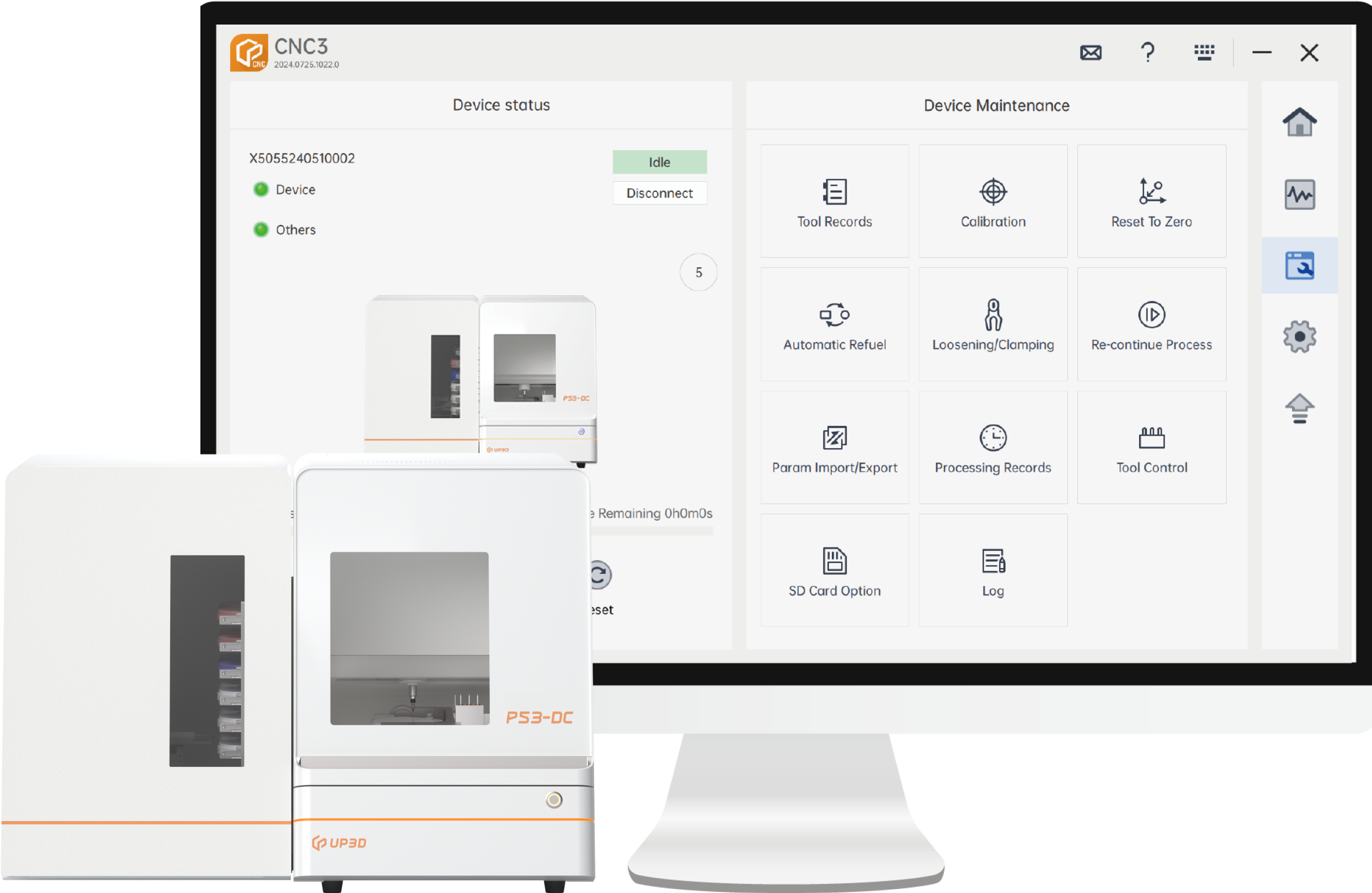

The Smart Material Management System streamlines production with one-click order import, automatically recognizing design type, color, and thickness for accurate sorting. Intelligent disc selection maximizes material usage, while optimized nesting minimizes waste and enhances efficiency for continuous milling.

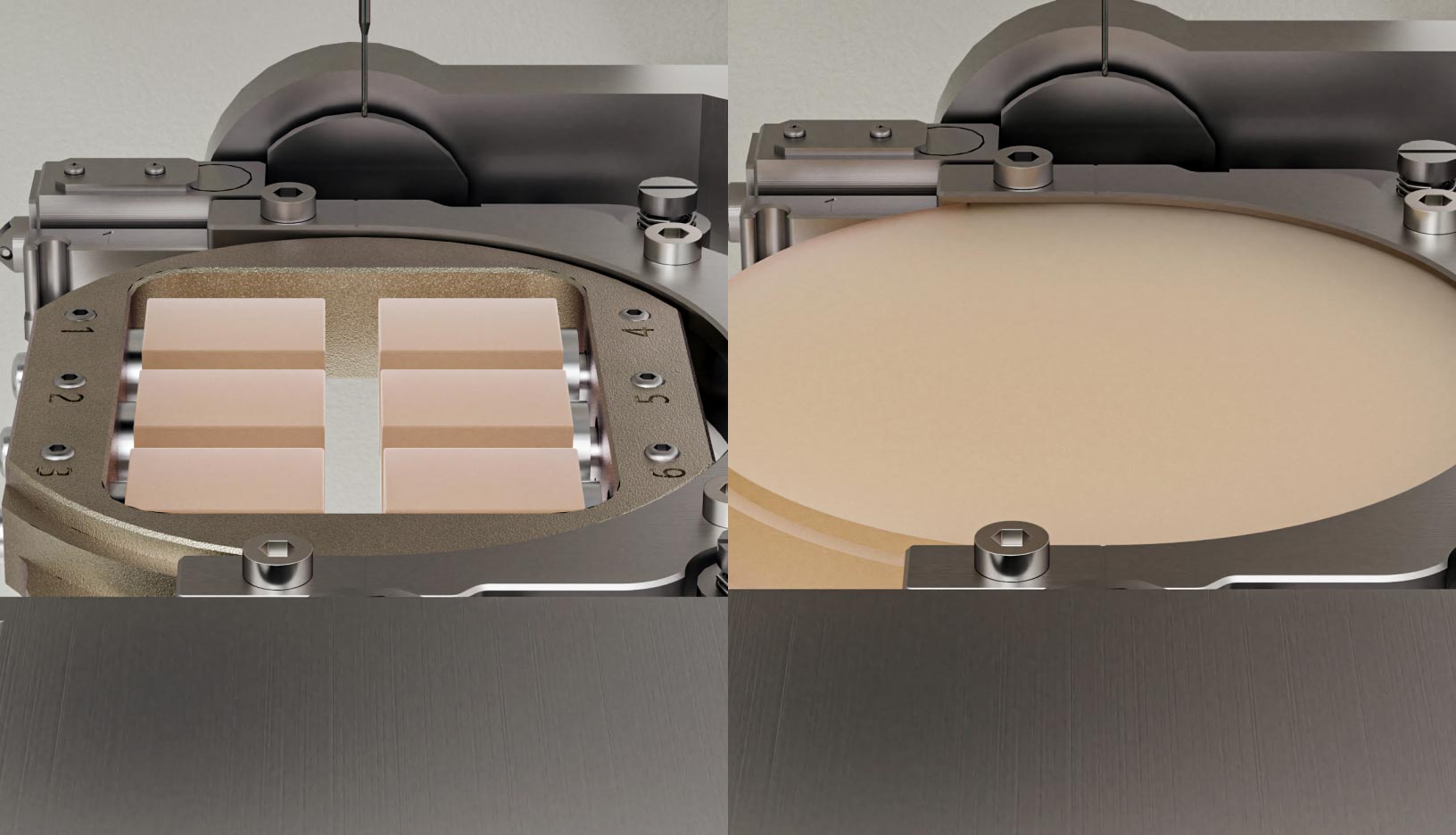

The C-clamp design expands buccal milling space, improves material nesting and edge utilization, and maximizes material savings, delivering greater economic benefits to dental labs.

.jpg)

With an 11-tool capacity, the automatic tool changer supports continuous milling across different materials, minimizing downtime, boosting efficiency, and ensuring precision and stability while reducing maintenance costs.

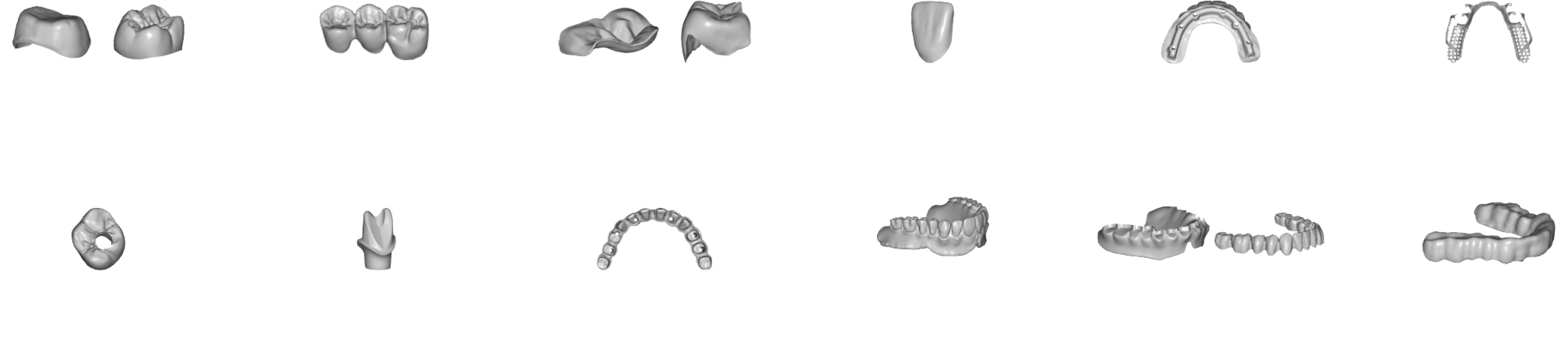

With a custom 0.2mm micro-carving tool and a 0.6mm extended milling tool, it precisely mills occlusal details, perfectly replicating tooth morphology.

Whether it's composite resin disc or block, the P53DC handles it with ease, providing greater flexibility for your dental lab.

Spindle Temperature Monitoring: Built-in CNC overload warning system prevents overheating and spindle damage.Advanced Spindle Protection: Precise pressure regulator ensures stable spindle cooling and air pressure, greatly extending spindle life and ensuring smooth operation at peak performance.